Page 3

Kulkoni, Inc.

UW v1610

WARNING: NEVER EXCEED WORKING LOAD LIMIT

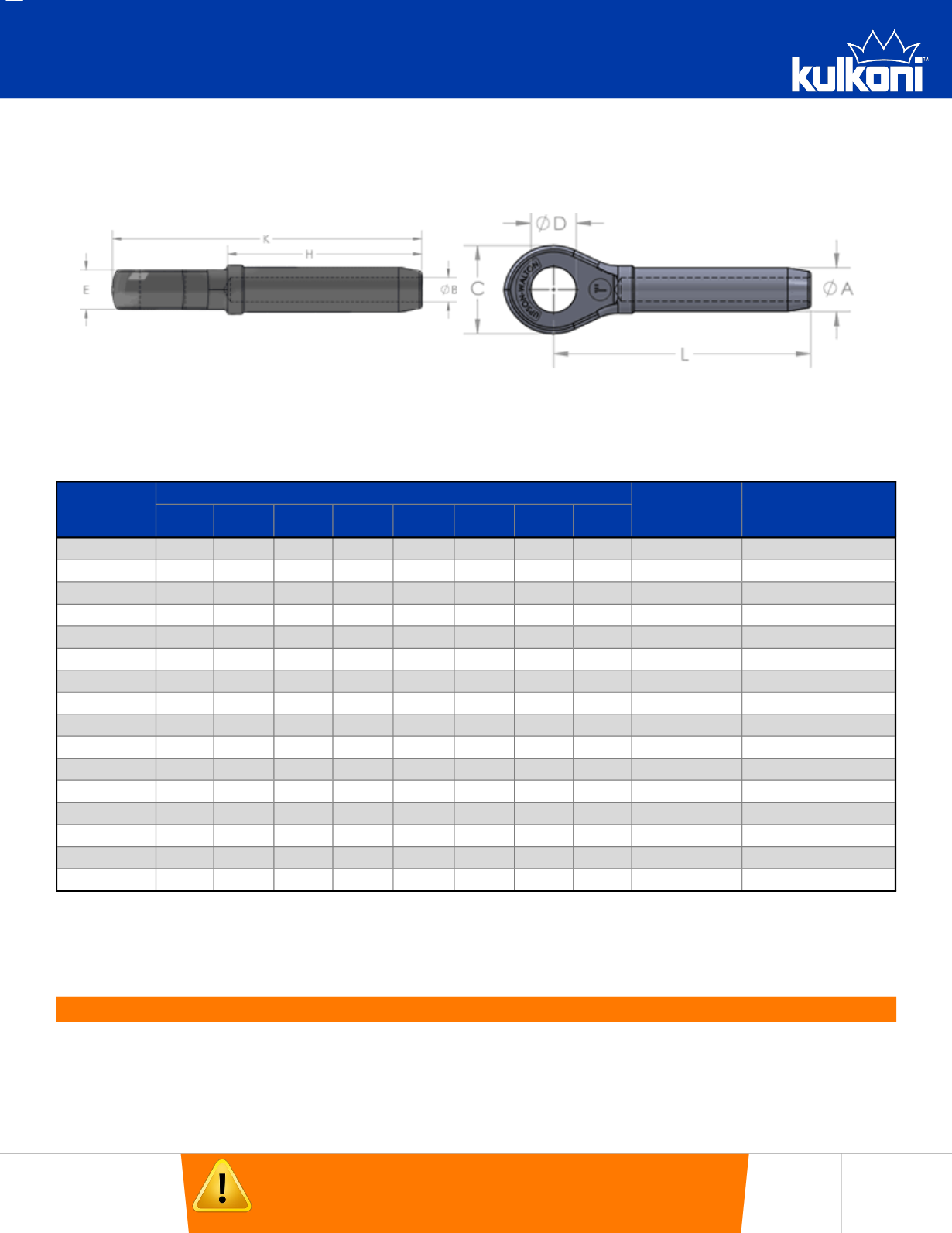

UPSON-WALTON™ CLOSED SWAGE SOCKETS

Read important warnings and information on pages 2-9 and page 33 of Kulkoni

general catalog v214.

DOMESTIC CLOSED SWAGE SOCKETS

Rope

Diameter

in Inches

Dimensions in Inches

Approx.

Weight Each

in Pounds

A/S*

MIN—MAX

A

B

C

D

E

H

K

L

1/4

0.50 0.27 1.44 0.75 0.50 2.13 4.38 3.50

0.34

0.428 - 0.460

5/16

0.77 0.34 1.69 0.88 0.69 3.19 5.50 4.50

0.79

0.678 - 0.710

3/8

0.77 0.41 1.69 0.88 0.69 3.19 5.50 4.50

0.78

0.678 - 0.710

7/16

0.98 0.48 2.00 1.06 0.88 4.25 6.94 5.75

1.45

0.865 - 0.910

1/2

0.98 0.55 2.00 1.06 0.88 4.25 6.94 5.75

1.38

0.865 - 0.910

9/16

1.26 0.61 2.50 1.25 1.13 5.31 8.75 7.25

2.78

1.115 - 1.160

5/8

1.26 0.67 2.50 1.25 1.13 5.31 8.75 7.25

2.75

1.115 - 1.160

3/4

1.55 0.80 3.00 1.44 1.31 6.38 10.38 8.63

5.00

1.365 - 1.420

7/8

1.70 0.94 3.50 1.69 1.50 7.44 12.13 10.13

7.50

1.490 - 1.550

1

1.98 1.06 4.00 2.06 1.75 8.50 13.75 11.50

11.20

1.740 - 1.800

1.1/8

2.25 1.19 4.50 2.31 2.00 9.56 15.25 12.75

15.80

1.990 - 2.050

1.1/4

2.53 1.33 5.00 2.56 2.25 10.63 17.25 14.38

23.00

2.240 - 2.300

1.3/8

2.80 1.45 2.52 2.56 2.25 11.69 18.88 15.75

31.00

2.490 - 2.560

1.1/2

3.08 1.58 5.50 2.81 2.50 12.75 20.38 17.00

39.00

2.740 - 2.810

1.3/4

3.39 1.86 6.75 3.56 3.00 14.88 24.00 20.00

52.00

2.990 - 3.060

2

3.94 2.11 7.75 3.81 3.25 17.00 27.50 23.00

90.00

3.490 - 3.560

* A/S indicates the proper dimension of A after swaging.

Swage Sockets are recommended for use on 6 x 19 or 6 x 36 IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire

ropes. They are also approved for use on galvanized bridge rope. Before using swage sockets with other type lay, con-

struction or grade of wire rope, it is recommended that the termination be proofloaded to prove the adequacy of the as-

sembly. Spheroidized annealed for cold swaging. Sockets properly applied have an efficiency rating of 100%. This rating

is based on the catalog breaking strength of wire rope.

Caution:

When attaching swage sockets to wire rope it is extremely important to follow recommended procedures.